Improving Urine Tube Handling With Automation – Sullivan Nicolaides Pathology

Sullivan Nicolaides Pathology is one of Australia’s largest and most respected diagnostic testing laboratories, regarded for their expertise in esoteric as much as routine testing. They are a member of the Sonic Healthcare Group, a leading global provider in pathology and laboratory medicine services.

The Situation

The Biochemistry Department at Sullivan Nicolaides Pathology main lab in Brisbane processes approximately 10,000 urine samples per week. 65% of these samples are received in a 9ml urine collection tube and the remainder received in containers of various sizes – mostly urine pots or large plastic bottles – which ultimately have to be manually poured off into 9ml collection tubes for subsequent analysis.

Urine tubes are centrifuged and then tested on one of 2 Abbott Architect® c16000 chemistry analysers. The Architects analyse for up to 10 different tests – including creatinine, albumin, urea nitrogen, total bilirubin, protein, calcium, magnesium, alkaline phosphates, and glucose.

Until recently, the technicians working in the urine testing area manually decapped and loaded the urine tubes into the Architect racks for analysis.

After the analysis was completed, each urine tube was unloaded in turn from the respective analyser rack, manually capped with a push on cap and then transferred into a storage rack for archiving. Samples are stored for 7 days at 4 deg C before being discarded.

Decapping and recapping up to 2,000 urine tubes per day and loading them into racks is a time-consuming task. Not only that, manually decapping and recapping such a large number of tubes daily was causing repetitive strain injuries (RSI) for the technicians.

The Solution

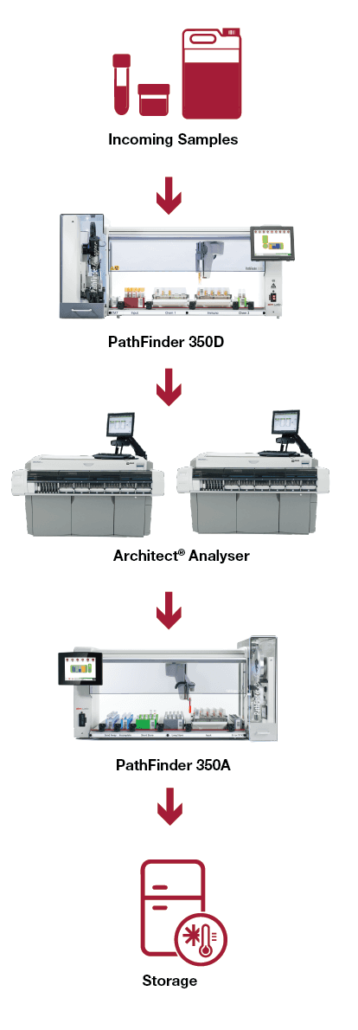

To free up the lab technicians from the tedium of decapping and recapping large numbers of tubes, Sullivan Nicolaides introduced a PathFinder 350D and PathFinder 350A, Aim Lab’s pre and post-analytical benchtop tube processing workstations into the urine section to automate this process.

Now, after centrifugation, the urine tubes are loaded onto the PathFinder 350D in either a 20 or 50 well PathFinder automation rack and the urine tubes are automatically decapped and placed directly into Architect racks in Carrier trays.

After testing has been carried out on the Architects, each Architect Carrier tray is transferred to the PathFinder 350A where the completed urine tubes are automatically foil sealed and archived into a PathFinder 50 well rack for ready for storage.

The Results

Introducing a tube handling automation solution into the Urine Testing Area has lead to several benefits:

The workload is now largely done by one person when previously it required two technicians.

There is more time available for the skilled technician to focus on other daily tasks that require their attention.

99% of the urine samples processed are decapped and capped (foil sealed) automatically, reducing the occurrence of repetitive strain injuries.

There have been efficiency gains through the introduction of a linear workflow (refer to image alongside).

Aaron Lentz, a technician in the urine testing area, has worked at Sullivan Nicolaides Pathology for over 20 years over which time he has seen substantial changes in the way lab operations are constantly evolving.

Since the introduction of the PathFinders into his workflow, Aaron’s daily life has become a little easier. He finds the PathFinder solution simple to use and reliable. “You can always be assured that the PathFinders will work and just get the job done”, says Aaron.